Daily maintenance of dispensing machine

作者:點膠機發布員???日期:2019-10-19 07:11???瀏覽:

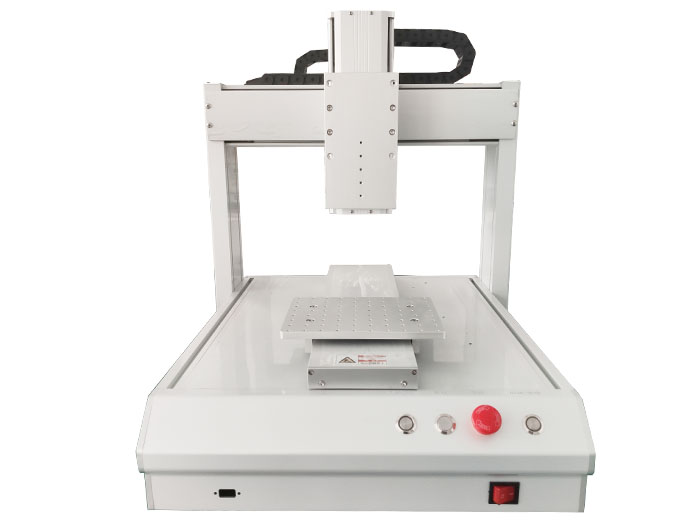

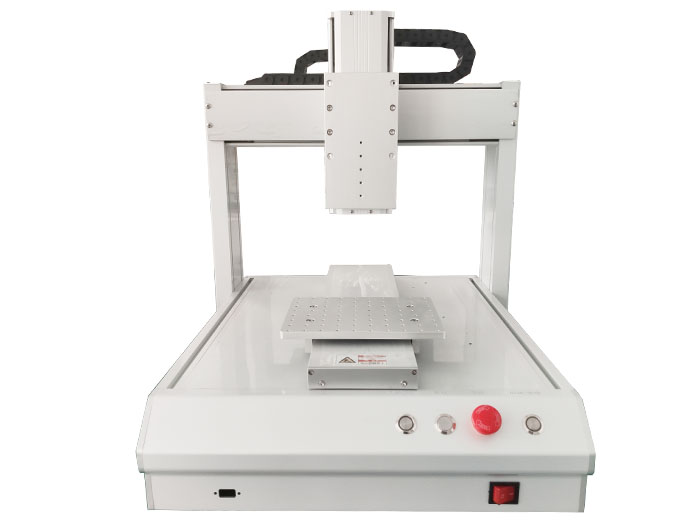

Maintenance of automatic dispensing machine has a direct impact on its service life, so doing a good job of maintenance and protection of dispensing machine can not only improve the quality of products, but also extend the service life of equipment, save a lot of expenses for enterprises. Next, let's discuss in detail how to maintain dispensing machine.

Clean the pipes when changing the rubber type. At this moment, the main thing is to close the feed valve, open the discharge valve, drain the remaining glue from the plastic barrel, close the discharge valve, open the feed valve, pour the cleaning solvent into the rubber barrel, the engine body, and press the solvent according to the usual operation form. Wash clean.

The atmospheric pressure is abnormal and water vapor is found. Please check the water vapor in the pressure regulator filter or check whether the pressure source is abnormal. Before using glue in many ways, please use a small amount to master the skills of the product, so as to avoid mistakes. When there is no problem in the experiment, a double-drop glue machine or a double-liquid glue filling machine is used for mass production; vacuum pump system is applied to the glue to remove bubbles in order to eliminate bubbles in the mixing process, or 10-20 minutes before operation, so as to eliminate bubbles in the mixing process in time and make the glue mix together more. Many.

The above content is the maintenance skills and some application knowledge of automatic dispensing machine. It is expected that after the enterprise purchases dispensing equipment, the relevant personnel will be trained in the maintenance of dispensing machine, which is not only conducive to the improvement of enterprise talent post technology, but also plays an active role in building an outstanding external image of the enterprise.

Clean the pipes when changing the rubber type. At this moment, the main thing is to close the feed valve, open the discharge valve, drain the remaining glue from the plastic barrel, close the discharge valve, open the feed valve, pour the cleaning solvent into the rubber barrel, the engine body, and press the solvent according to the usual operation form. Wash clean.

Clean the pipes when changing the rubber type. At this moment, the main thing is to close the feed valve, open the discharge valve, drain the remaining glue from the plastic barrel, close the discharge valve, open the feed valve, pour the cleaning solvent into the rubber barrel, the engine body, and press the solvent according to the usual operation form. Wash clean.